Advancing Precision: The Future of CNC Automation

- DMAC Machining

- Mar 14, 2024

- 3 min read

Relentless innovation is driving CNC Automation and transforming manufacturing technology. From its inception in the 1940s to the high-tech heights it's reaching today, we delve into how this field has evolved, the current challenges, and where it's headed.

CNC Machining: From Military Precision to Manufacturing Revolution

Since the 1940s, CNC machining has undergone a remarkable transformation, evolving from rudimentary, cumbersome machines to the sophisticated and precise models utilized today. The integration of Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) technologies was initially adopted by the United States Air Force. This innovation sought to create a more cost-efficient method to produce complex aircraft components. The 1960s and 1970s marked a pivotal moment in the history of CNC machining. These advancements revolutionized manufacturing processes by enabling designers to translate complex geometries into precise machine instructions.

FMS and CIM: The 80s and 90s Tech Boom in CNC Automation

The evolution of CNC automation continued through subsequent decades, fueled by the relentless pursuit of efficiency and precision in manufacturing. In the 1980s and 1990s, integrating robotics and other cutting-edge technologies further enhanced the capabilities of CNC machines. This era saw the emergence of flexible manufacturing systems (FMS) and computer-integrated manufacturing (CIM), ushering in a new era of automation and productivity.

Beyond the Military: CNC's Commercial Breakthrough Across Industries

The widespread adoption of CNC machining has transcended its initial military applications, permeating virtually every sector of the commercial world. In aerospace, CNC machine shops are indispensable for developing cutting-edge designs and components for space exploration, satellite communications, and aircraft manufacturing. Likewise, the medical field relies heavily on CNC machining for precision manufacturing of medical devices, prosthetics, and implants, contributing to advancements in healthcare and patient outcomes.

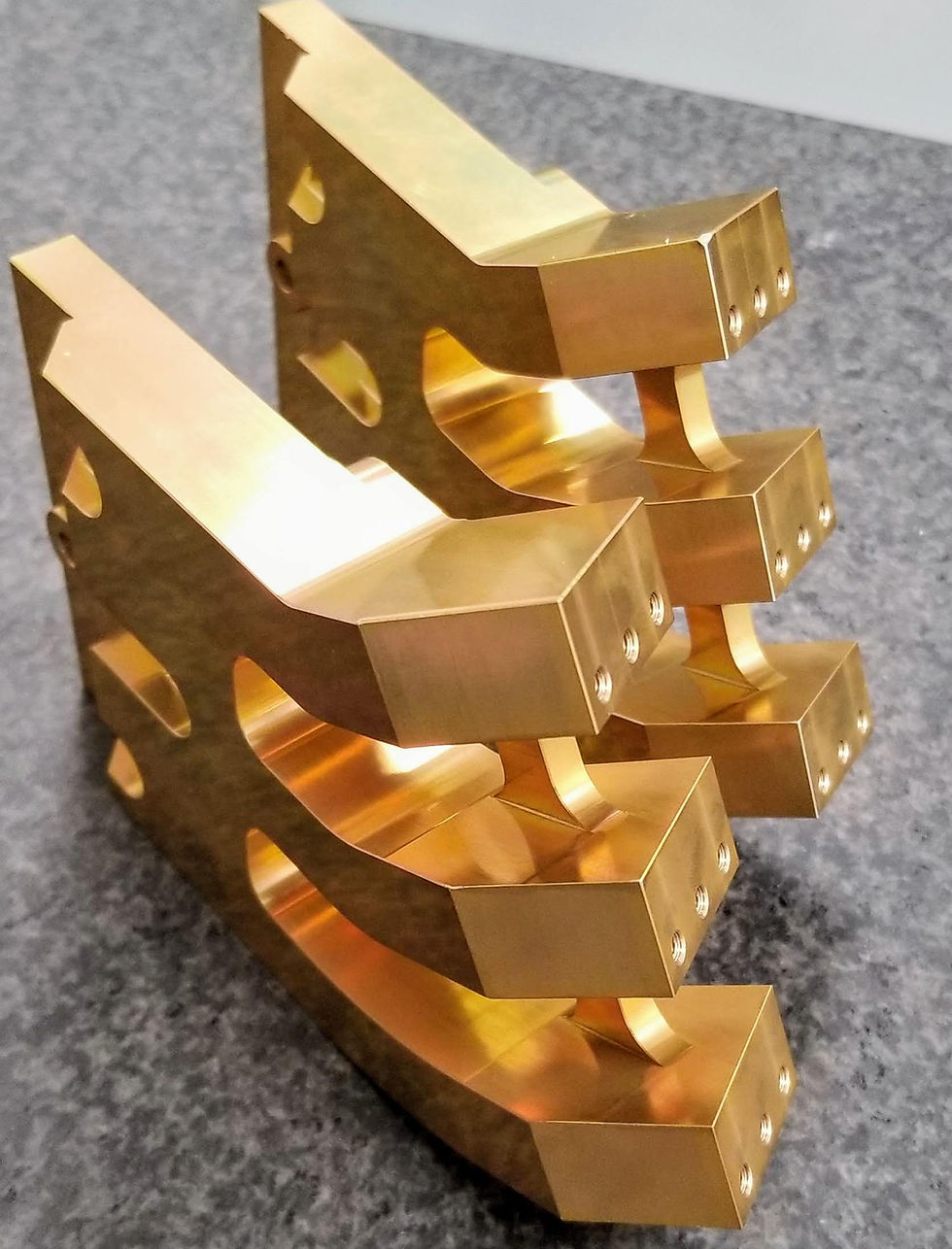

DMAC Machining's Commitment to Excellence in Small-Batch CNC Production

At DMAC Machining, our dedication to excellence in small-batch production is the cornerstone of our philosophy. We collaborate closely with clients to bring their innovative designs to life, leveraging our expertise in CNC machining to overcome technical challenges and deliver superior quality parts. Our investment in state-of-the-art 5-axis machines empowers us to achieve unparalleled precision and complexity, setting a new standard for production.

Navigating the Skilled Workforce Challenge in CNC Machining

Despite the numerous benefits of CNC automation, the industry faces several challenges. Chief among these is the recruitment and training of skilled personnel. The intricacies of CNC machining require continuous learning and adaptation, placing a premium on workforce development and training initiatives. Additionally, the substantial startup costs associated with CNC machines pose a barrier to entry for many small businesses, necessitating careful financial planning and investment strategies.

Understanding Material Certifications in CNC Manufacturing

The landscape of material certifications adds another layer of complexity to CNC machining operations. These certifications, which encompass parameters such as tensile strength, heat treatment, and alloy composition, are essential for ensuring the quality and reliability of machined parts. Navigating the maze of certification requirements requires expertise and attention to detail, underscoring the importance of robust quality assurance processes in CNC machining operations.

The Next Chapter in CNC Automation: Emerging Technologies and Prospects

Looking ahead, the future of CNC machining is brimming with possibilities. Advancements in computer technology and applications promise to further revolutionize the industry, enabling machines to produce increasingly complex parts with minimal human intervention. The relentless pursuit of precision and efficiency will continue to drive innovation in CNC machining, shaping the manufacturing landscape for generations to come. As we embark on this exciting journey, DMAC Machining remains committed to pushing the boundaries of what's possible and delivering excellence in small-batch production today and beyond.

.png)

Comments