Titanium vs Copper: Navigating Material Challenges in CNC Machining

- DMAC Machining

- Jun 14, 2024

- 3 min read

When it comes to CNC machining, the choice of material can significantly impact the process and the final product. Two commonly used metals in this field are titanium and copper, each with its unique properties and challenges. Navigating the complexities of CNC machining and understanding the differences between these materials is crucial, and at DMACMachining, these challenges are met head-on.

Machining Efficiently Through Toughness and Tool Wear

Titanium's toughness is a double-edged sword in CNC machining. While it ensures the durability of the final product, it also puts a strain on cutting tools. The hardness of titanium leads to increased tool wear and necessitates frequent tool changes. DMACMachining, with its commitment to precision, invests in high-quality, wear-resistant tools to mitigate this challenge and ensure consistent machining performance.

In contrast, copper, known for its softness and malleability, presents a different set of challenges. While copper does not wear down tools as quickly as titanium, its tendency to gum up and create built-up edges on cutting tools can hinder machining processes. This requires frequent tool cleaning and careful selection of cutting fluids to prevent sticking and ensure smooth operations.

The Effects of Heat Generation and Thermal Expansion

The heat generated during the CNC machining of titanium can be a significant hurdle. Titanium has a low thermal conductivity, meaning the heat generated tends to concentrate in the cutting zone. This, in turn, can lead to thermal expansion, affecting the dimensional accuracy of the machined parts. DMACMachining tackles this challenge through strategic toolpath planning, coolant optimization, and employing cutting strategies that manage heat effectively to maintain tight tolerances.

Copper, on the other hand, has excellent thermal conductivity, which means it dissipates heat more efficiently than titanium. This property reduces the risk of thermal expansion and helps maintain dimensional accuracy. However, copper's thermal conductivity also means that it can quickly conduct heat away from the cutting area, potentially causing the cutting tools to cool down rapidly and resulting in uneven wear or even cracking. DMACMachining addresses these issues by optimizing cutting speeds and feeds to balance the heat generation and dissipation.

Workholding and Vibration Solutions for Titanium and Copper

Titanium's low modulus of elasticity makes it prone to vibrations during machining. Securely holding the workpiece becomes crucial to prevent chatter and maintain surface finish. DMACMachining employs specialized workholding solutions that provide stability and reduce vibrations, ensuring that the CNC machines can operate with the precision their clients' demand.

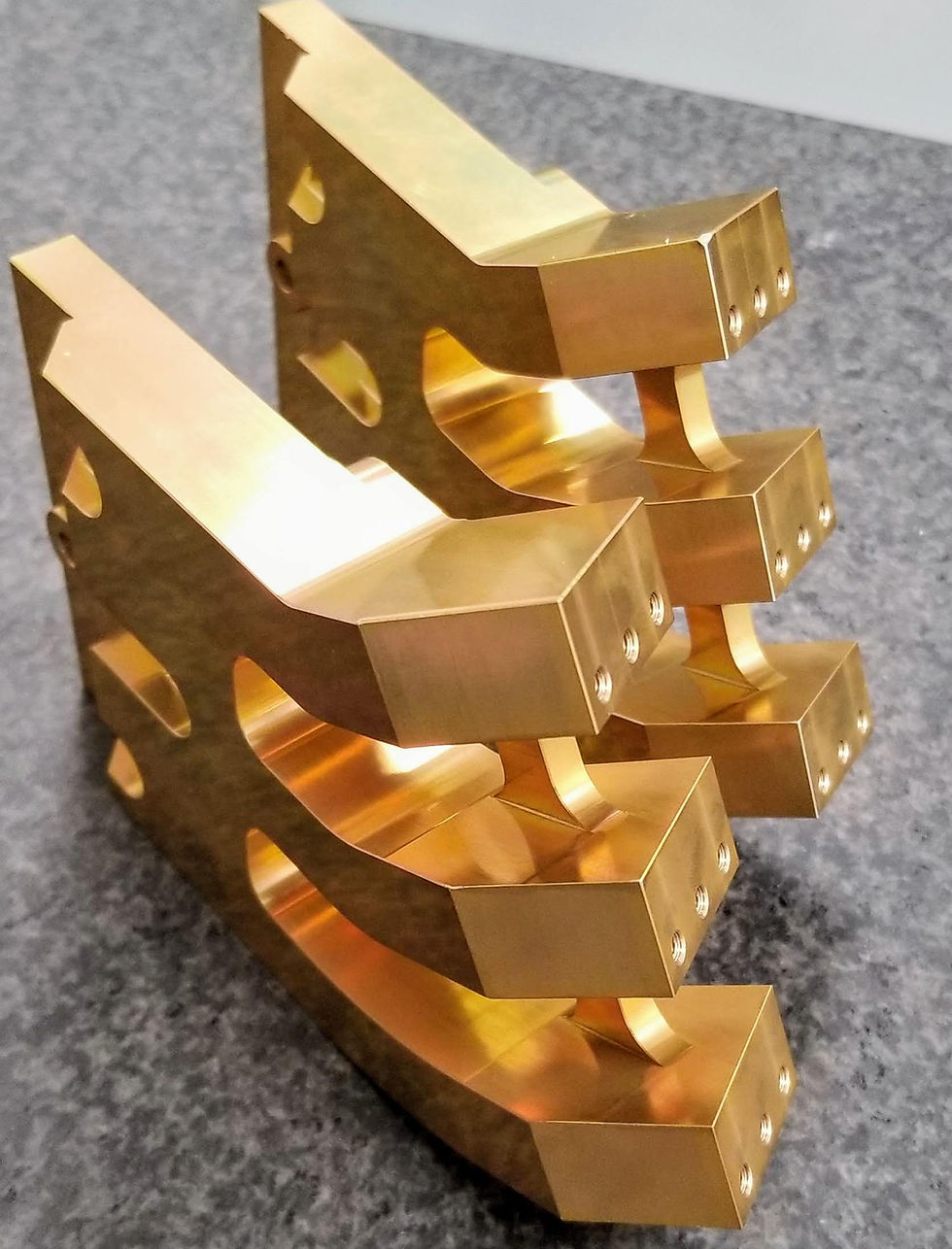

Copper, with its higher modulus of elasticity compared to titanium, is less prone to vibrations. However, its ductility can make it difficult to clamp securely without causing deformation. Our craftsmen utilize customized fixtures and workholding techniques to securely grip copper parts without causing damage, ensuring that both materials can be machined with precision and minimal distortion.

Combating Chemical Reactivity

Titanium's chemical reactivity, especially at high temperatures, poses challenges for traditional cutting fluids. We address this issue by utilizing advanced cutting fluids and techniques designed to enhance tool life and maintain surface integrity, even when working with the chemically reactive nature of titanium.

Copper is less chemically reactive than titanium, simplifying the selection of cutting fluids. However, copper can react with certain coolants and cutting fluids, leading to surface staining or corrosion. DMACMachining carefully selects compatible cutting fluids and employs proper coolant management practices to maintain the quality and appearance of machined copper parts.

Project-specific Challenges

Each project at DMACMachining comes with its unique set of challenges, and when titanium is involved, project-specific considerations become paramount. Factors such as the alloy of titanium, the complexity of the design, and the desired surface finish all influence the CNC machining approach. Our expertise lies not only in the ability to tackle common challenges but also in tailoring solutions to the nuances of each individual project.

Similarly, machining copper requires an understanding of its specific properties and project requirements. Copper alloys vary widely in their machinability, and the design complexity and desired finish can significantly impact the machining strategy. DMACMachining leverages its experience and adaptability to customize machining processes for copper, ensuring high-quality outcomes regardless of the project's demands.

Triumph Over Material Challenges at DMACMachining

CNC machining with titanium at DMACMachining is not for the faint of heart, but it's a challenge embraced with enthusiasm. By understanding and navigating the complexities of titanium, we ensure the result is not just a product of precision but a testament to mastery over materials that push the boundaries of what's achievable in CNC machining. Similarly, the ability to skillfully machine copper demonstrates DMACMachining's versatility and commitment to delivering exceptional results across a range of materials.

Whether dealing with titanium's robustness or copper's malleability, DMACMachining continues to deliver prototypes that not only meet but exceed the expectations of industries where microns truly matter.

.png)

Comments