From Pixels to Precision - How Expert CAD Programming Shapes Innovation at DMACMachining

- DMAC Machining

- Feb 1, 2024

- 1 min read

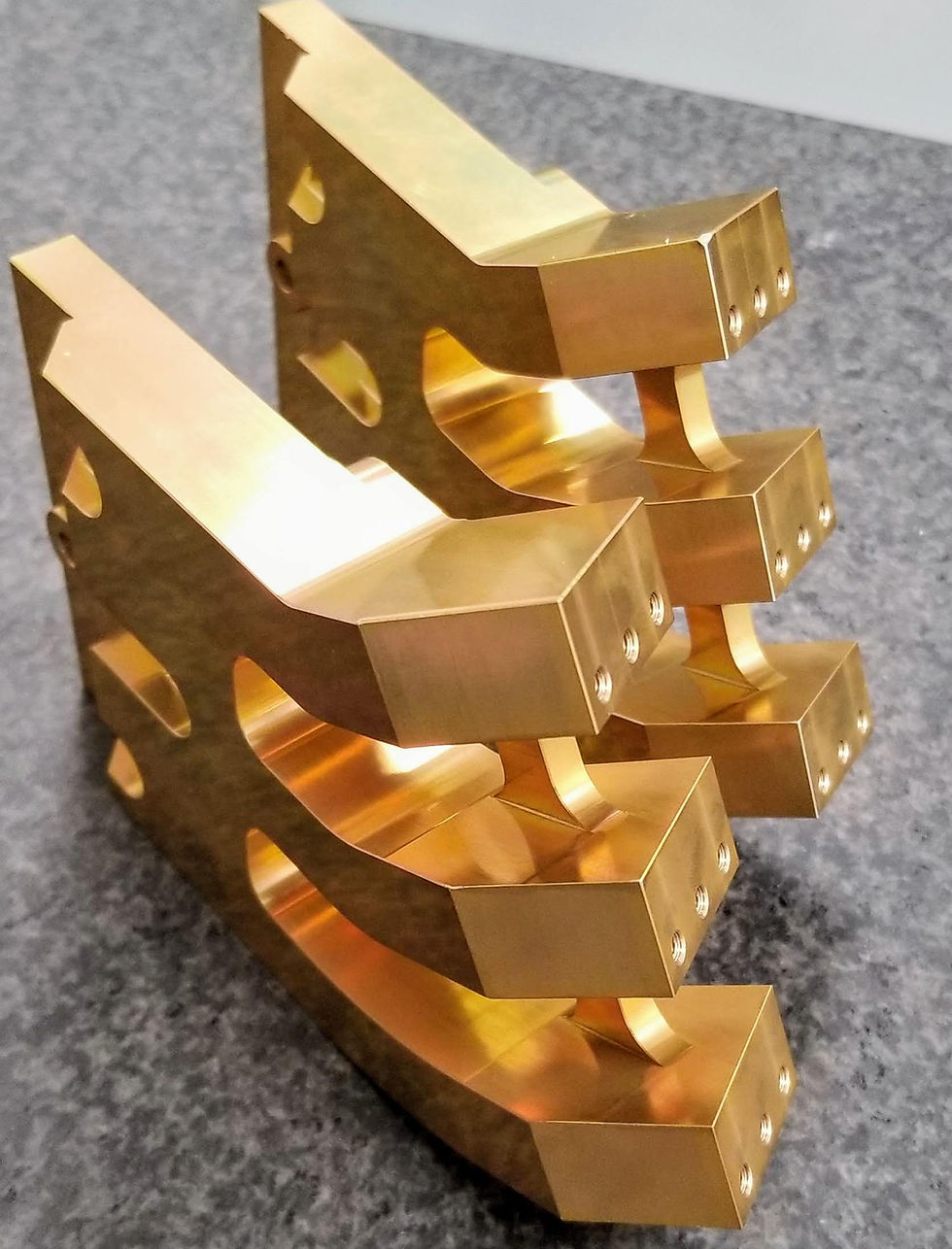

The journey from a digital concept to a physical masterpiece at DMACMachining begins with Computer-Aided Design (CAD) programming. In this article, we explore the intricacies of how 3D modeling in CAD translates into the precision-engineered physical pieces that define DMACMachining's commitment to excellence.

Digital Blueprint: The Foundation of Precision

CAD software serves as the digital canvas where ideas take shape. DMACMachining's CAD programmers meticulously craft a digital blueprint, defining every contour, dimension, and detail of the desired prototype. This digital model is the foundation for the entire CNC machining process, laying the groundwork for translating virtual designs into tangible reality.

CAM Programming: Bridging the Digital-Physical Gap

Computer-Aided Manufacturing (CAM) programming acts as the bridge between the digital and physical realms. At DMACMachining, CAM programming involves the generation of toolpaths and machining instructions based on the CAD model. This step is critical, as it determines how CNC machines will precisely carve, cut, and shape the material to transform the virtual design into a tangible piece.

Precision Toolpath Planning

The magic of precision at DMACMachining lies in the strategic planning of toolpaths. CAM programmers optimize tool movements to maximize efficiency, minimize material waste, and achieve the desired level of precision. Every cut is meticulously calculated, ensuring the CNC machine moves with exactitude to bring the digital design to life.

Tolerances and Iterative Refinement

DMACMachining's commitment to precision extends to defining tolerances within the CAD programming. Tolerances, often measured in microns, are programmed to match the specifications of the final product. The iterative refinement of the CAD model and corresponding CAM programming allows for adjustments and enhancements to meet the stringent requirements of each project.

.png)

Comments