Vacuum Fixturing in CNC Machining: Flexibility, Efficiency, and Engineering Around Limitations

- DMAC Machining

- Jun 19, 2025

- 3 min read

At DMAC Machining, where prototype work drives creativity and innovation, vacuum fixturing has become a powerful tool in our workholding strategy. When used correctly, vacuum fixtures can radically transform the way a part is machined—especially in small-batch, quick-turn environments like ours.

From reducing material waste to enabling complex part geometry, the upsides are compelling. But like any tool, vacuum fixturing has its engineering challenges that must be carefully managed.

Why Use Vacuum Fixturing In CNC Machining?

Traditional CNC machining setups rely heavily on mechanical clamps or vises to secure a part. While reliable, they also impose physical limitations on the part’s geometry—what can be clamped, where clamps can be placed, and how much stock needs to be added just to hold the part in place. Vacuum fixturing removes many of these barriers.

Pros of Vacuum Fixturing

1. Thinner Material, Less Waste: Since the workpiece doesn’t need to be clamped around the perimeter, we can machine thinner sheets or plates without additional stock. This reduces cost and waste—especially useful in expensive materials like copper or titanium.

2. Freedom of Design: Parts can be held flat without needing extra geometry for clamping. This is a major advantage in prototype work where parts may have irregular or unconventional shapes not suited for a traditional vise.

3. Quick Setup for Short Runs: For one-off or low-volume parts, vacuum fixtures can often be faster to build and set up than custom mechanical fixtures. This aligns with our mission of delivering parts quickly, without compromising on complexity.

The Physics Behind the Fixture

Vacuum fixturing works by removing air from a sealed chamber beneath the part, allowing atmospheric pressure to press the part down and hold it in place. But it's important to understand the difference between full vacuum (theoretical, impossible in practice) and what we use: total vacuum—the best achievable vacuum using reliable shop-grade equipment.

· At sea level, 1 atmosphere equals roughly 14.7 PSI.

· At higher elevations (like 5,280 ft, or one mile above sea level), the atmospheric pressure drops to about 12 PSI—only ~0.81 atmospheres.

This means your maximum possible clamping force per square inch is inherently lower at elevation, and it’s never the full 14.7 PSI even at sea level, since most vacuum pumps achieve between 25–29 inHg, not a perfect 30.

Limitations and Considerations For Vacuum Fixturing

Cutting Force vs. Holding Power

Vacuum fixturing is best suited for materials that easier to machine—like plastics, aluminum, or thin copper. Harder materials like stainless steel require more aggressive cutting, which can exceed the holding force of the vacuum, especially if the part's surface area is small.

Part Size Matters

The more surface area under vacuum, the more holding force you gain. Small parts with limited contact area are not ideal for vacuum alone and may require hybrid solutions (mechanical + vacuum clamping).

Surface Seal IntegrityEven a tiny leak—dust, a chip, or a slightly warped part—can break vacuum pressure. Good sealing is crucial, which is why we machine our own fixture plates with precision grooves for O-rings and use high-quality gasketing material to maintain a reliable seal.

Making It Work at DMAC

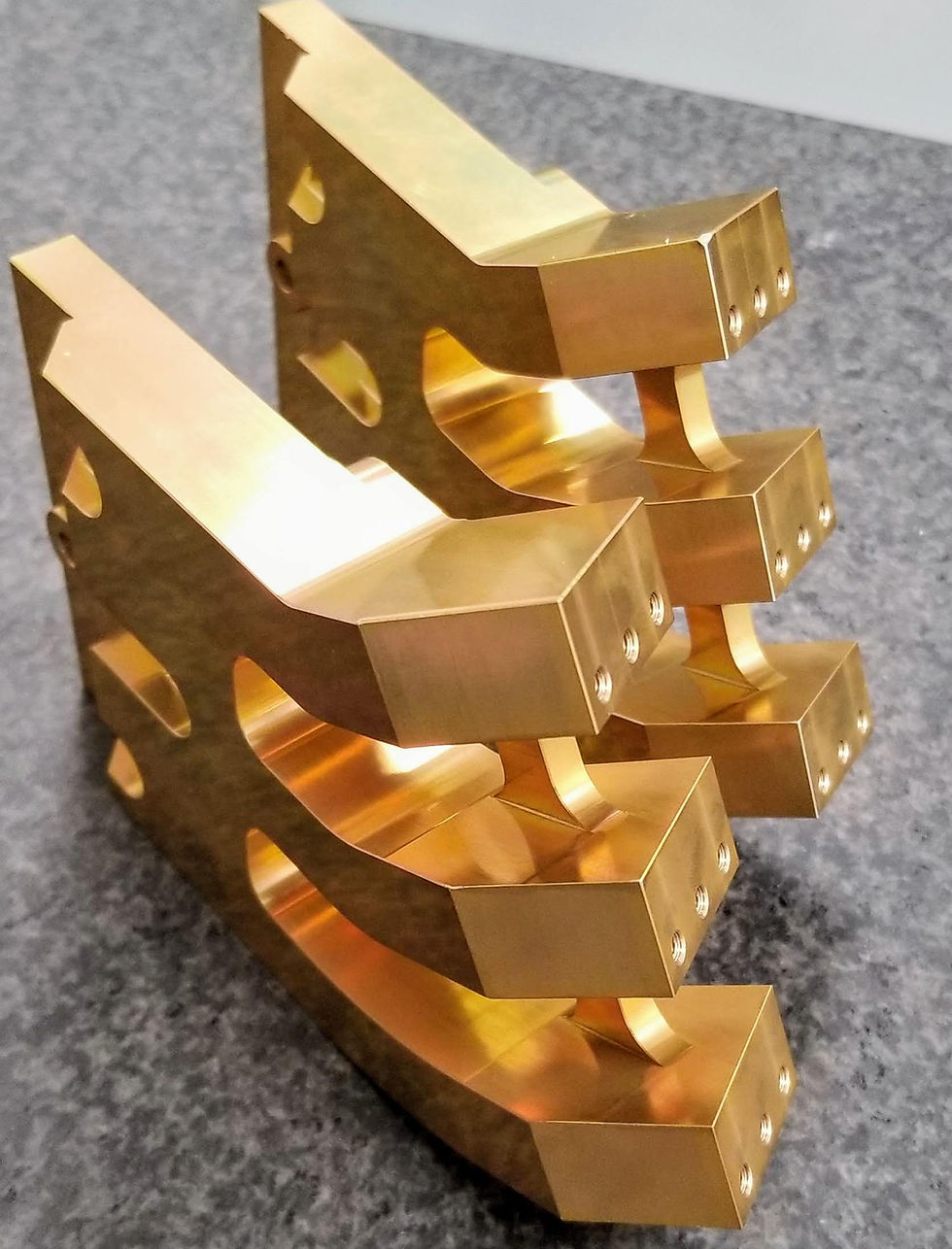

At DMAC, we design and build our vacuum fixtures in-house, using a modular approach that allows us to adapt to different part geometries. We often pair vacuum hold-downs with creative nesting, dowel pins, or mechanical stops to manage lateral forces during more aggressive toolpaths.

We don’t chase perfect vacuum—we engineer for total vacuum and design within its known limits. This mindset allows us to safely and reliably push the envelope on part geometry, setup speed, and material efficiency.

Vacuum fixturing isn’t a silver bullet, but when used intelligently, it’s a game-changer—especially in the world of prototypes where every second and every gram of material counts. At DMAC Machining, our use of vacuum technology helps clients turn complex concepts into tangible parts, quickly and efficiently, while keeping material waste and setup costs to a minimum.

.png)

Comments