Best Practices for Modeling Parts for CNC Programming: Additive vs. Subtractive Machining

- DMAC Machining

- Sep 14, 2024

- 3 min read

When creating parts for CNC programming, understanding the differences between modeling techniques is crucial for ensuring manufacturability, cost-efficiency, and optimal performance. Whether using additive methods like 3D Printing or subtractive techniques like CNC machining, how you model your parts directly impacts the outcome. With DMAC Machining's advanced 5-axis CNC machines, even the most complex parts can be manufactured with exceptional precision and efficiency.

Additive Machining: 3D Printing

Additive machining, commonly seen in 3D Printing, builds parts layer by layer using a variety of materials such as plastics, metals, and resins. This method enables the creation of complex internal structures and intricate designs.

Advantages of Additive Machining

Complex Geometries:

3D Printing excels at producing highly intricate shapes, internal cavities, and lattice structures, often with fewer constraints.

Material Efficiency:

Since material is only added where necessary, there's minimal waste.

Rapid Prototyping:

Ideal for quick iterations and design validation, especially for complex or one-off designs.

Disadvantages of Additive Machining

Surface Finish & Tolerances:

Surface finish can be rough, and achieving tight tolerances may be difficult.

Material Constraints:

Not all materials are available for additive processes, particularly high-strength metals.

Strength & Durability:

Additively manufactured parts may have lower structural integrity due to the layer-by-layer process.

Subtractive Machining: CNC Machining

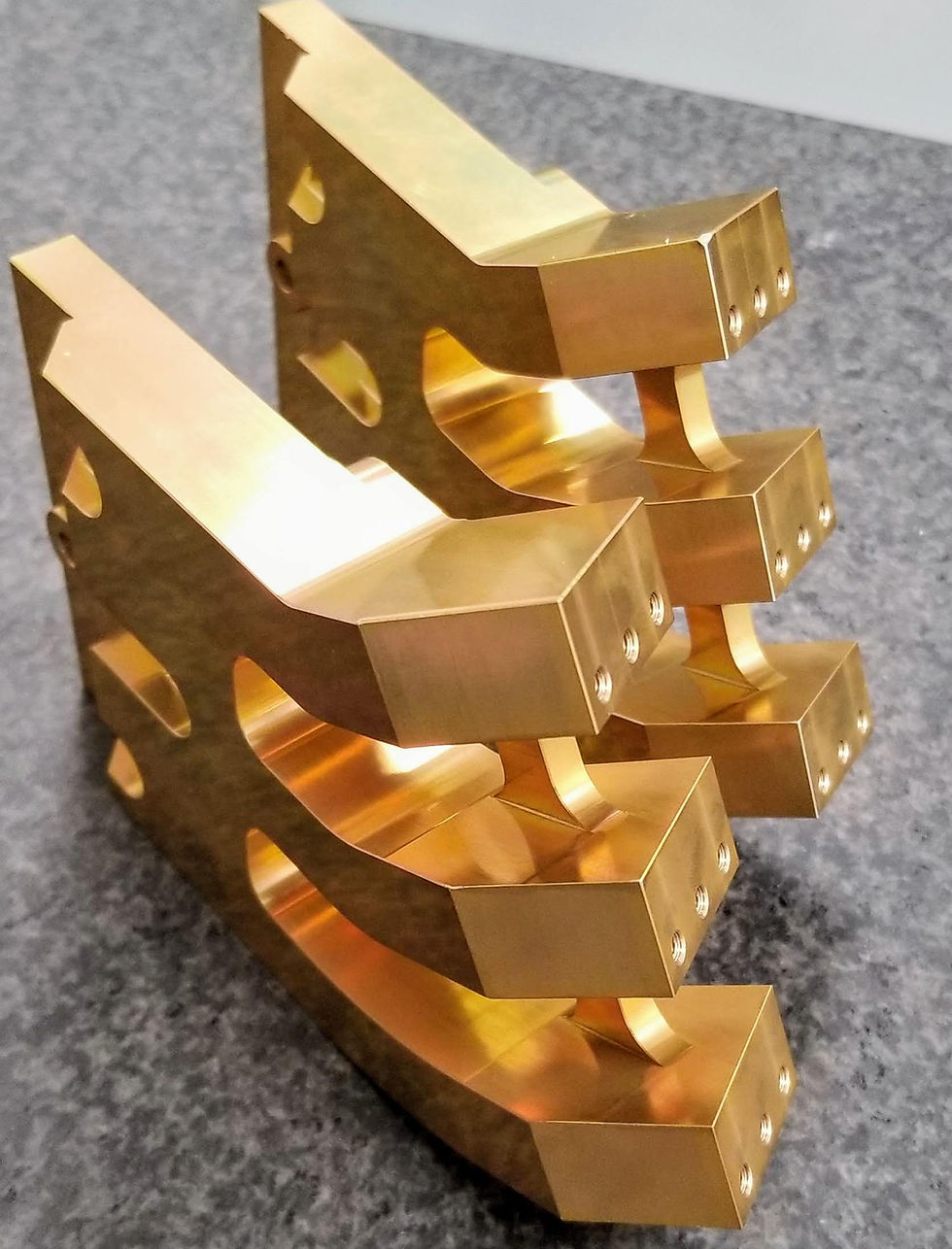

Subtractive machining, such as CNC machining, removes material from a solid block (stock) to create a part. With DMAC Machining's 5-axis CNC machines, the capability to manufacture even the most complex geometries is greatly expanded.

Advantages of Subtractive Machining

Precision & Surface Finish:

CNC machining delivers parts with exceptional surface finishes and tight tolerances.

Complexity & Access:

While traditional 3-axis machines have limitations, DMAC's 5-axis CNC machines can create highly complex geometries by accessing the part from multiple angles in a single setup.

Material Variety:

CNC machining supports a wide range of materials, including high-performance metals such as aluminum, titanium, and stainless steel.

Structural Integrity:

Since parts are machined from solid stock, they tend to be stronger and more durable than additively manufactured parts.

Disadvantages of Subtractive Machining

Material Waste:

Subtractive machining generates more scrap material compared to additive processes.

Setup Time:

Some complex parts may require multiple setups with traditional CNC machines, but 5-axis machining drastically reduces the need for repositioning.

Key Differences Between Additive and Subtractive Machining

Best Practices for Modeling CNC Parts

1. Design for Precision

With 5-axis CNC machines, you can create highly precise parts in fewer setups. Design your parts to take full advantage of the machine's ability to reach multiple angles and reduce the need for reorientation.

2. Optimize for Tooling Access

Traditional 3-axis machines limit access to certain features, but DMAC's 5-axis capabilities allow for greater design freedom. Use this model for parts with undercuts, angled features, and complex geometries without worrying about accessibility issues.

3. Choose the Right Material

While 3D Printing may handle basic materials like plastic, CNC machining, especially with 5-axis machines, allows for more durable and high-performance materials. Consider strength and durability in your material selection for critical parts.

4. Keep Wall Thickness in Check

For both additive and subtractive methods, ensure walls are neither too thin nor too thick. In 3D Printing, thicker walls increase durability, while in CNC machining, 5-axis technology can more easily handle thinner walls without compromising precision.

5. Simplify When Possible

Even though 5-axis CNC machines offer greater flexibility, simplifying your part design can save time and reduce costs. Complex designs are still more time-consuming to manufacture, even with advanced machinery.

6. Plan for Post-Processing

While 5-axis CNC machining provides excellent surface finishes, additional processes like heat treatment or coating may still be required. Design your models with any post-processing in mind to avoid dimensional changes.

The Power of 5-Axis CNC Machining

While additive machining, like 3D Printing, excels in rapid prototyping and complex internal structures, CNC machining remains the top choice for high-precision, durable parts. With DMAC Machining's advanced 5-axis CNC machines, even the most intricate and geometrically challenging parts can be manufactured with unparalleled precision.

By leveraging best practices in modeling and the latest technology in CNC machining, you can ensure that your parts meet all requirements while remaining cost-effective and manufacturable.

.png)

Comments