Laser Engraving vs. CNC Machining for Part Marking

- DMAC Machining

- Dec 15, 2024

- 3 min read

When it comes to marking part numbers or other identifiers on components, both laser engraving and CNC machining offer unique advantages and challenges. Choosing the right method depends on factors like material, precision, durability, and cost. Here's a comprehensive review of the pros and cons of each method.

Pros of Laser Engraving for Part Marking

1. Enhanced Visibility:

Laser engraving produces high-contrast markings that are often more legible than CNC-machined etchings, especially on polished or dark surfaces.

2. Color Options:

Certain metals, like titanium, can display colors through laser engraving due to heat oxidation, offering an aesthetic edge over machining.

3. Versatility:

- Ideal for intricate details such as logos, QR codes, and barcodes.

- Supports a variety of TrueType fonts, enabling custom and stylistic text designs.

- Effective for small, precise details thanks to its fine precision capabilities.

4. Speed:

Marking with a laser is significantly faster than machining, making it ideal for high-volume production runs.

5. Material Compatibility:

Works on a wide range of materials, including metals, plastics, ceramics, and even glass, without requiring tool changes.

6. Non-Contact Process:

The laser doesn't physically touch the material, reducing wear on equipment and minimizing the risk of part deformation.

7. Annealing Mark Capability:

On materials like steel, stainless steel, and titanium, laser marking can change the material's color without removing it, a process known as annealing marking.

8. Engraving Flexibility:

Lasers can also physically engrave by removing material, providing depth when necessary.

9. Coating Ablation:

On coated materials, such as anodized aluminum, the laser can ablate the coating in the marking area for a clean, precise finish.

Cons of Laser Engraving for Part Marking

1. Surface-Level Markings:

Lasers create shallow marks that may wear over time in abrasive environments.

2. Setup Costs:

High-powered lasers can be costly to purchase and maintain.

3. Heat Effects:

Improper settings can cause discoloration or slight warping on sensitive materials.

4. Material Limitations:

Aluminum without coatings does not change color, so engraving is typically required for uncoated aluminum parts.

Pros of CNC Machining for Part Marking

1. Durability:

Deep, robust etchings are more resistant to wear and fading, making them ideal for parts exposed to harsh conditions or frequent handling.

2. Variable Depth Control:

CNC machining allows for precise control over the depth of markings, offering robust, permanent identifiers.

3. Material Versatility:

Effective on metals, plastics, and composites, providing flexibility for various industrial applications.

4. Customization Options:

Allows for unique designs, including custom lettering or part numbers, with a focus on durability.

5. Engraving for Aluminum:

CNC machining is particularly suited for physically engraving uncoated aluminum parts to create durable markings.

Cons of CNC Machining for Part Marking

1. Longer Cycle Time:

Material removal is slower compared to laser marking, resulting in increased production times and costs.

2. Tool Wear:

Engraving hard materials can lead to frequent tool maintenance or replacement.

3. Process Complexity:

Requires careful setup, particularly when dealing with variable material thickness or irregular shapes.

Shared Benefits of Laser Engraving and CNC Machining

Part Identification: Both processes ensure parts are marked clearly, making them easy to identify during assembly, maintenance, or inventory.

Reorder Simplicity: Markings facilitate straightforward reordering by providing clear and permanent part numbers or identifiers.

Brand Recognition: Marked parts serve as a branding tool, reinforcing company identity and professionalism.

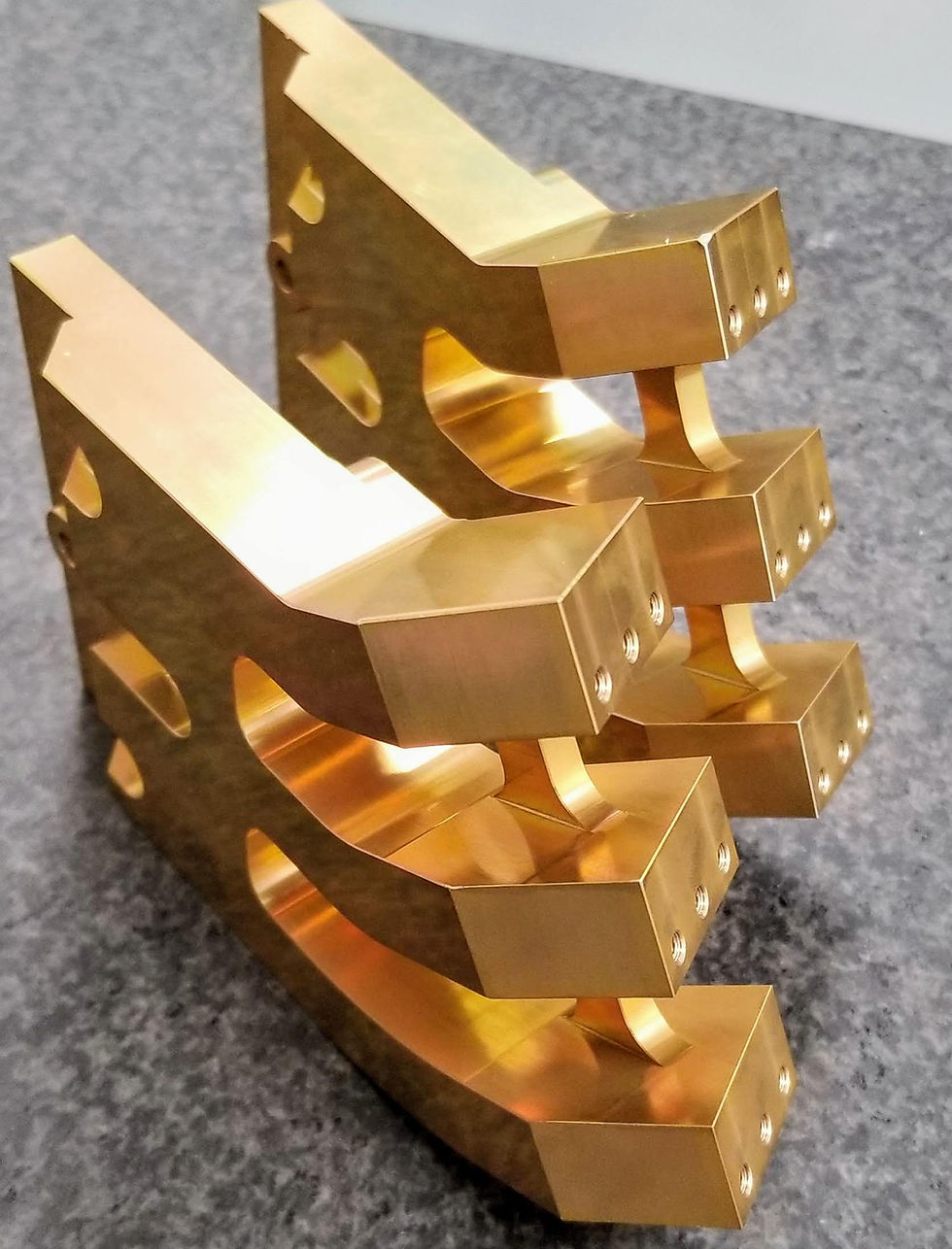

DMAC Machining's Expertise in CNC Machining and Laser Engraving

At DMAC Machining, we offer the best of both worlds. Our advanced capabilities include both CNC machining and laser engraving, allowing us to tailor part marking solutions to meet the unique needs of any project. Whether you require the speed and precision of laser engraving or the durability of CNC-machined markings, we have the technology and expertise to deliver exceptional results.

Choosing between laser engraving and CNC machining often comes down to the project's specific requirements. Laser engraving is often the go-to for high-speed, versatile, and visually striking results. However, CNC machining offers unparalleled durability for robust, deep, and permanent markings.

.png)

Comments